Home | Equestrian and polo complexes

equestrian and

polo complexes

Design Construction Renovation Maintenance of equestrian surfaces

Gregori International renovates and manufactures technical floors, even in the most remote places on the planet, for all types of surfaces, open or not, for permanent or temporary use: equestrian arenas and riding arenas, paddocks, walkers, longe rings, Havrincourt rings, trotting tracks, gallop tracks, racecourses, polo fields, etc.

our services

for equestrian surfaces

Preliminary studies, choice of substrate, construction work, maintenance

For almost 20 years, Gregori International has been building top-of-the-range equestrian surfaces combining performance, durability and safety. With references in Greece, Spain, France, Qatar, the United Arab Emirates and Central Asia, Gregori International has significant experience in the turnkey construction of equestrian surfaces, from preliminary studies through to maintenance.

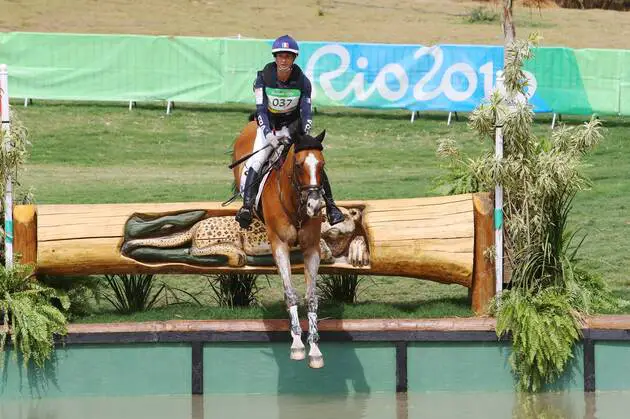

C’est le procédé FIBERSoil qui a, en particulier, permis de construire les surfaces destinées aux Jeux Olympiques d’Athènes en 2004.

Sable ou gazon, la technique FiberSoil répond aux standards à atteindre dans le cadre d’entraînement et de compétitions internationales

- Stage 1:Preliminary study - design

- Step 2: Drainage and irrigation

- Step 3:Reinforced mix

- Step 4: Levelling

- Step 5: Runway maintenance

- Stage 6:Supplies, lices and starts

Gregori International has developed the FIBERsoil technique, which combines performance, durability and safety, particularly suited to racecourses, polo fields and cross-country tracks, which can be combined with both grass and sand surfaces.

Turf

FiberSoil

Classic Fiber technology for high-performance turf

- Tear strength and divot reduction

- Excellent drainage, with no interruption to play even in heavy rain

- Adaptation to extreme climates

- High quality and comfort for horse and rider

- Possibility of intensive use

FiberSoil

Grey Fiber

Grey Fiber technology for soft, reinforced sand

- Can be incorporated with any type of sand

- Runway reinforcement and stabilization

- Flexible impact for horse and rider

- Better soil moisture conservation

- Water savings for irrigation

Other projects

equestrian surfaces

Gregori International renovates and manufactures technical floors, even in the most remote places on the planet, for all types of surfaces, open or not, for permanent or temporary use: equestrian arenas and riding arenas, paddocks, walkers, longe rings, Havrincourt rings, trotting tracks, gallop tracks, racecourses, polo fields, etc.

How to choose an equestrian floor?

To choose an equestrian floor, it is necessary to combine safety, stability and comfort according to the discipline practiced.

Intended use : each discipline requires a different texture and bearing capacity (firmer ground for dressage, softer ground for jumping or training).

The composition of the soil : calibrated sand, textile fibres, geotextiles, organic or mineral binders depending on the desired level of damping.

Drainage and watering : essential to maintain stable humidity and avoid dust or compaction.

Maintenance and frequency of use : the ground must remain homogeneous and easy to level to preserve the health of the horses.

What are the steps in the construction of an equestrian floor?

The main steps must guarantee stability, shock absorption and regularity to ensure safety and performance.

- Site investigation and site preparation : analysis of the natural soil, levelling, and definition of slopes for water evacuation

- Installation of drainage: installation of drains and filter materials to prevent water stagnation and ensure that the soil is always passable.

- Installation of the foundation layers : gravel, sand or technical mixture ensuring the bearing capacity and flexibility of the soil.

- Laying the working layer : a mixture of calibrated sand, textile fibres or stabilising additives, depending on the use (dressage, show jumping, trotting, endurance, etc.).

- Compaction, levelling and watering : finishes guaranteeing the flatness, cohesion and regularity of the equestrian ground.

Which soil for your quarry?

The objective is always to obtain a draining, stable and flexible soil, composed of good calibrated sand and possibly a stabilizer to guarantee safety and longevity.

- Calibrated equestrian sand : the most used base, offering good lift and natural cushioning.

- Fibre-reinforced flooring : a mixture of sand and textile fibres to strengthen cohesion, limit dust and improve flexibility.

- Geotextile or geo-fiber flooring : ideal for intensive or professional quarries, it maintains constant humidity and perfect flatness.

- Organic or natural soil : suitable for outdoor quarries with little use, requiring regular maintenance.

What soil for a racecourse?

For a racecourse, the ground must offer speed, safety and regularity. There are generally four types of soils

- Natural sand floors : they are very common, offer good flexibility and effective drainage. Their composition (particle size, humidity, depth) must be adapted to the speed and type of stroke.

- Fibre-reinforced floors : a mixture of sand and synthetic fibres for better cohesion, constant bearing capacity and increased stability, even under heavy load.

- Floors made of shavings or stabilised organic materials : Used for training tracks, they reduce wear and tear and limit dust.

- All-weather floors (mix of sand + specific binders): designed to remain passable in all weather conditions.

What ground for a cross country course?

The ground must combine adhesion, bearing capacity and shock absorption. We are looking for a stabilized, well-drained natural soil, reinforced if necessary by sand, fibers or amendments to guarantee safety and resistance in all weathers.

Which floor for a gallop track?

For a gallop track, a very regular, draining and efficient soil is preferred, generally based on silica sand or fibre mixtures. The objective is to ensure speed, safety, impact absorption and consistency of the terrain whatever the weather.

The choice of ground depends on the type of races (flat, jump, trot) and the level of intensity.

- The fine-grained calibrated sands ensure flexibility and comfort of stride, while facilitating drainage.

- Fibre mixtures (sand + textile fibres) improve soil cohesion, limit dust and guarantee homogeneous load-bearing capacity, even after heavy rains.

- The all-weather tracks, combining sand, binders and technical additives, allow continuous use, regardless of weather conditions.

- Some synthetic surfaces used on major international racecourses provide optimal stability and reduce maintenance.

Which floor for a horse riding arena?

The main solutions:

- Calibrated equestrian sand : the most common base, offering good bearing capacity and simple maintenance.

- Fibre-reinforced flooring : a mixture of sand and textile fibres that improves cohesion, limits dust and guarantees a soft and even surface.

- Geotextile or geo-fiber flooring : ideal for intensive or professional rides, as it maintains homogeneous humidity and reduces wear.

- Stabilised or additive soils : enriched with natural or synthetic binders, they improve soil performance and reduce the frequency of watering.

How to choose the covering of your equestrian floor?

The choice is determined according to several criteria:

- The use of the field : a dressage arena requires a firm and precise ground, while a jumping or lunge work field favours softer cushioning.

- The materials used : calibrated sand, silica, textile microfibers, geotextiles or stabilizing additives depending on the expected performance and the climate.

- Water management : drainage and controlled humidity are essential to maintain bearing capacity and limit dust.

Maintenance frequency : some technical mixtures reduce the need for watering and harrowing.

Which equestrian soil does not require watering?

The most effective solutions:

- Floors treated with natural or synthetic binders : they limit dust and maintain the compactness of the soil.

- Dry fibre floors : the mixture of sand and technical textile fibres retains ambient moisture and improves stability without frequent watering.

- Floors with organic binders : designed for indoor rides or training tracks, they guarantee constant working comfort and reduce maintenance.

This type of coating ensures good load-bearing, controlled flexibility and high durability, while promoting responsible water management.

What is the price of an equestrian flooring?

The price of an equestrian floor covering varies greatly depending on the type of floor, the use (leisure or competition), the existing terrain, the desired finish, etc. the type of soil (simple sand, fibre-reinforced sand, stabilised all-weather soil),

- the surface,

- existing or future foundations,

- associated equipment (drainage, waterinf, geotextile, etc.),

- the level of finish and use (club, competition, professional).

- The quality of the sand or mixture used (grain size, purity) influences the price.

- Whether or not there is an automatic drainage or watering system.

- The initial land (earthworks, levelling, complex operation): the more prepared it is, the higher the cost.

- The local climate and the constraints of use (intensive training, competition) which require more efficient materials.

Here is an indicative estimate per m²:

- Entry-level (simple sand on lightly worked ground): ≈ €10 to €20/m².

- Intermediate range (calibrated sand + drainage + minimum foundation layer): ≈ €20 to €35/m².

- High-end (fibre or hybrid soil, stabilisation, integrated watering, complete drainage): ≈ €30 to €50/m² or more depending on complexity.

How to maintain equestrian floors?

Maintaining an equestrian floor means guaranteeing its regularity, safety and longevity despite daily use. Here are some best practices

- Control humidity : appropriate watering or sub-irrigation preserves the cohesion of the sand and limits dust.

- Aerate and loosen the deeper layers to improve flexibility and drainage.

- Clean up organic debris (droppings, leaves, roots) that alter the soil structure.

- Monitor drainage and curbs to prevent water pooling and runway deformation.

The frequency depends on the use (training, competition, indoor arena or outdoor arena) and the type of surface (simple sand, fibre, geotextile).

When to water an equestrian soil?

Equestrian soil should be watered as soon as its surface becomes dry, dusty or loses flexibility. The objective is to maintain regular humidity to guarantee stability, comfort and durability of the coating.

Water before intensive sessions or competitions to improve flexibility and reduce hoof heating.

In hot weather, plan to water daily or every other day, ideally early in the morning or in the evening to limit evaporation.

In winter or in indoor arenas, adjust the frequency according to the ambient humidity and the degree of soil compaction.

Regularly check the moistening depth (approx. 10 to 15 cm) to ensure a homogeneous soil.

Automatic watering or sub-irrigation systems allow for more regular and economical water management.